Hari heliko txertaketak

Bidali kontsulta

Installing Helical Thread Inserts right means using the correct STI tap, mandrel, and tang break-off tool. Don’t overtighten them during installation—just get them snug without cranking down too hard. For maintenance, use the torque specs for the insert’s threads, not the base material you’re putting them into. Check the threads now and then for damage or dirt. If you need to service them, clean the threads carefully. When they’re installed correctly, these inserts don’t need much upkeep and will keep your fasteners secure through lots of assembly and disassembly cycles.

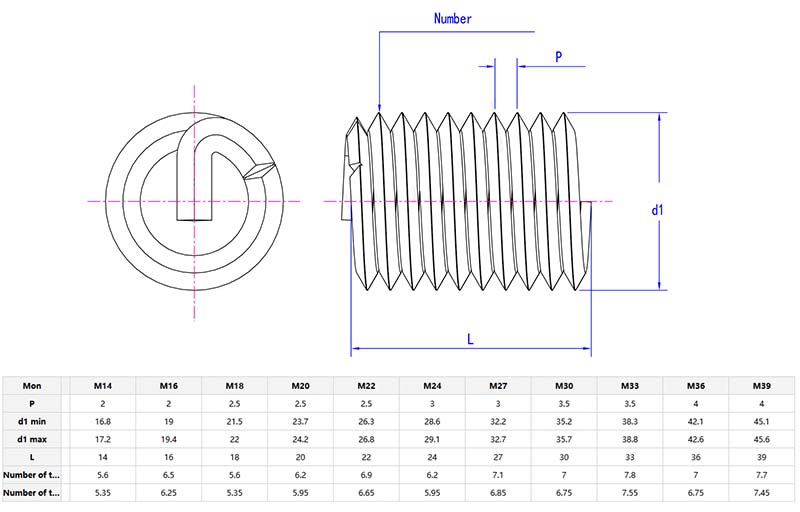

Product details and parameters

Helical Thread Inserts are solid tools for engineers.

They turn weak threads into solid joints that handle vibration, wear and tear, and rust well.

Fixing parts instead of replacing them – and cutting machine downtime – saves money.

They offer more design options and make products last longer.

These inserts provide support for internal threads that are often used in repair and upgrade equipment.

FAQ

Q: Do helical thread inserts comply with international standards and certifications (e.g. ISO, DIN, aerospace standards)?

A: Good manufacturers make this to key international standards – like ISO 9001 and specific ones such as DIN 8140 for metric sizes or aerospace specs like NASM 33537.

Our give you certificates (CoC) showing:

Where the material came from

The heat treatment done

That they meet size measurements

For your job, always double-check with your supplier:

The exact standard needed (e.g., ISO 14399 for high-strength bolts)

Any required certifications (like NADCAP in aerospace)